Bending, lifting and emptying; the employees of one of our clients were used to the daily ritual of physically demanding work. Their job was to empty the heavy rolling containers full of organic streams. While this was an essential part of the process, it was not the most attractive aspect of the job. Inefficient, unsafe and even a source of dissatisfaction among these hard-working workers.

A tipping point

This brought the company to a tipping point. Literally and figuratively. Should they continue down the same path, shrug and accept that "work is work"? Or was there an opportunity to innovate, change and improve? They chose the latter.

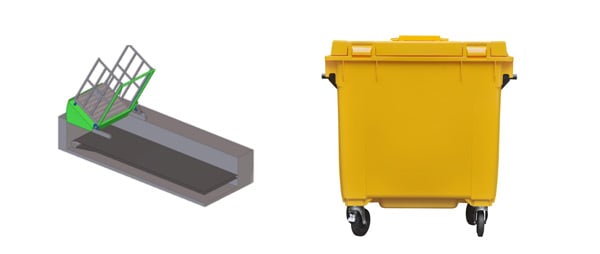

Investment was made in a new tipping system for the roll containers. An innovative solution that allowed the roll containers to be emptied easily and safely on a conveyor belt.

The investment in a new tipping system for the roll cages reduced internal handling by up to 25%.

Satisfied employees

The effect was immediate. Where previously faces were tense from the effort of lifting, satisfied smiles now appeared. Productivity improved and overall workplace satisfaction was higher than ever before. By implementing the tilt system, we improved employee health and well-being.

Fewer operations, more happy clients

The result in numbers? A significant 25% reduction in their internal operations. After this success, we plan to implement the tilt system at other clients as well. We like to see more happy faces on the shop floor of our clients.

Learn more

Would you like to learn more about our approach or go over the possibilities for your organization in a no-obligation meeting? Make an appointment now with Marco de Groot, Circular Economy Officer Logistics at Milgro.

Would you like to learn more about our approach or go over the possibilities for your organization in a no-obligation meeting? Make an appointment now with Marco de Groot, Circular Economy Officer Logistics at Milgro.