Many companies have waste from sticker carriers, glassine, as a residual product of the labeling process. The sticker carriers cannot be properly separated and therefore often end up in the residual waste. How do we ensure that sticker carriers get a better destination? We offer four solutions with advantages and disadvantages in this case. Are you reading along?

The challenge

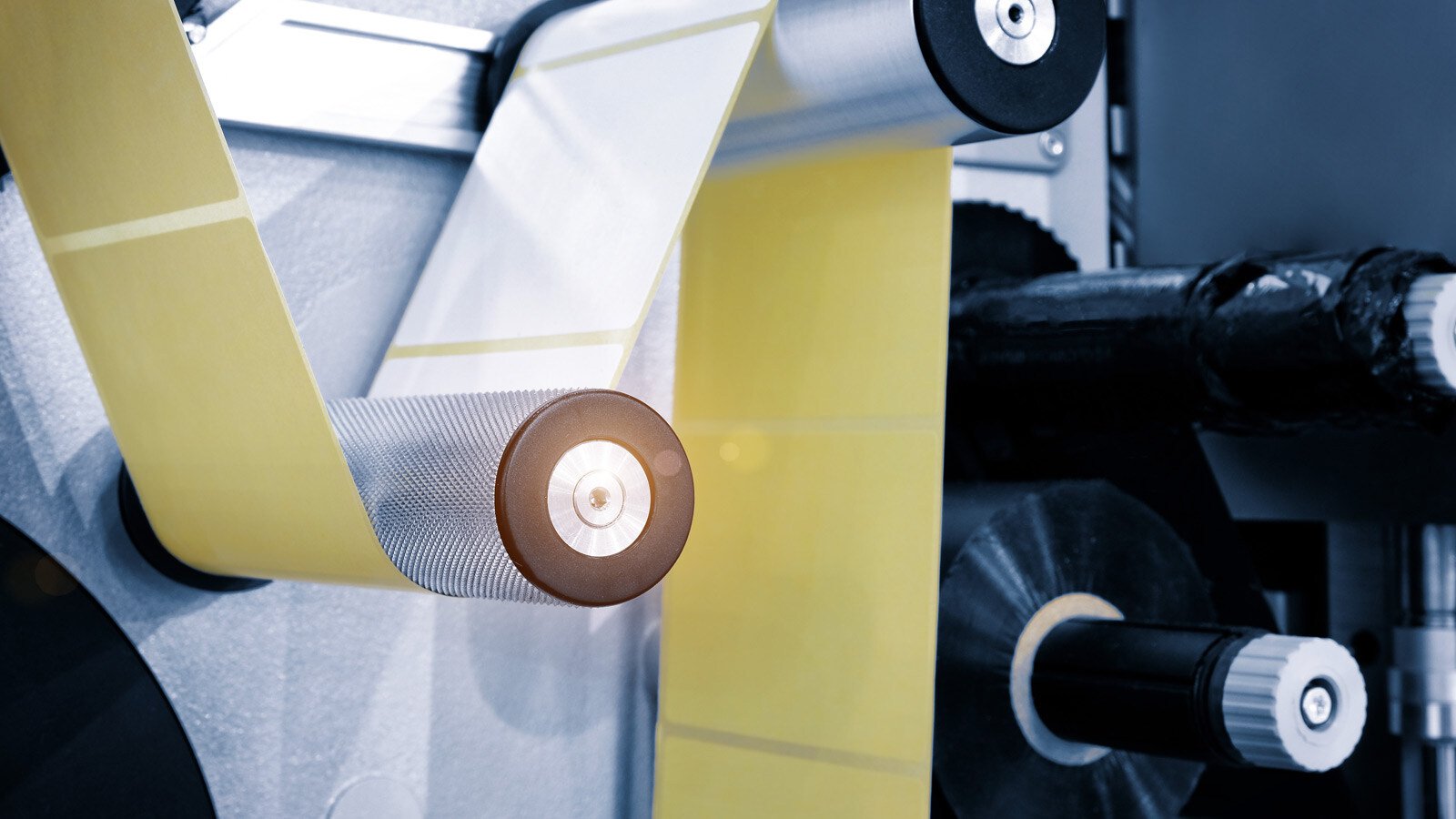

Sticker backing paper ensures that a label retains its self-adhesiveness. This is a very useful feature and many production/logistics companies use it. But during the labeling process, the labels are removed from the sticker backing paper, creating a significant amount of waste. The sheet on which the label sticks, glassine paper, usually yellow, cannot be separated from paper and cardboard, nor from plastic foil. For this reason, in most cases it ends up as residual waste.

To reduce sticker or label waste, companies can implement several strategies. Which strategy fits best depends on the sector and the organization. Below we discuss four options that build up to the most sustainable option.

1: Handling of stickercarriers

One option is to collect the sticker carrier paper and put it through a shredding installation that makes chips of the sticker paper to fill gift baskets, for example. While this temporarily reduces the waste flow, it is ultimately not a permanent solution because the filler material is ultimately discarded as well. This method postpones waste production but does not completely solve the problem. It can be more sustainable.

2: Replacement with foil sticker carriers

A second option would be to purchase other labels and replace the typical yellow sticker carriers with foil sticker carriers. Replacing yellow sticker carriers with foil sticker carriers requires minimal adjustment to the process, as most printers can easily handle this adjustment. This foil can be recycled into new foil.

However, recycling is not always sustainable, which is why we prefer to look at options that use fewer raw materials in the first place.

3: Using linerless labels

A third, innovative solution that fits better into that picture is linerless labels without backing paper. These labels use a special coating that ensures that the stickers stick themselves with the help of water. This allows us to reduce raw material consumption as close to the source as possible.

The solutions described so far are coming step by step closer to a form of labeling that reduces raw material consumption to zero. We are happy to help you reduce consumption as close to the source as possible. Could the use of printed labels be further or even minimized altogether?

4: Laser printing on packaging

In the field of labels, there has been a recent development in which steps are being taken in the use of laser printers. These machines print the message directly onto the destination box or packaging, meaning information is printed but no label is required.

Conclusion

We prefer to reduce raw material consumption as close to the source as possible. It is useful to look at purchasing. If it is not feasible within an organization to stop using labels, there are also solutions that opt for better materials that can be separated more easily so that as little residual waste as possible is created. Sticker carriers are a difficult waste stream. Are you dealing with this as an organization? Milgro likes to think along and pays attention to the context of your company. Together we will find a suitable and effective solution.

Tips or ideas?

Do you have any tips or ideas for preventing waste flows? Or does your company have an innovative way to make labeling waste-free? Let us know! We will include your suggestions, tips and solutions in our live blog in which we discuss innovative solutions for various waste flows.