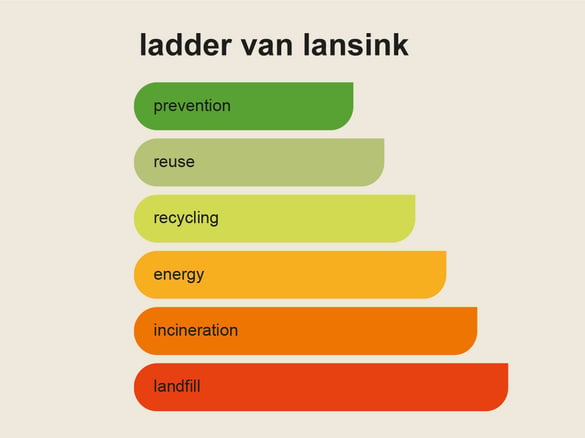

Since its introduction in 1979, Lansink's Ladder has been the standard for the waste hierarchy. At the time, the use of the model led to new insights into waste management. Now that we are embarking on the transition from a linear to a circular economy, it is good to take a closer look at the classics. The same goes for Lansink's Ladder. How does it hold up in the prelude to a circular economy?

History Ladder van Lansink

Back to the beginning. In 1979 Member of Parliament Ad Lansink introduced the nationally and internationally accepted preferred ranking for waste processing. Lansink previously worked as a biochemist on the theme of waste. In 1993, the model was included in the Environmental Management Act, which forms the basis for the National Waste Plan (LAP).

Explanation Ladder van Lansink

The preferred model, as the word implies, indicates preference for waste processing. The higher the step, the higher the preference. The ladder is divided into three categories, in which prevention, i.e. preventing a product from becoming waste, and reuse are the highest attainable. And incineration and dumping of waste is the least desirable.

Read also

Why a waste prevention plan is a must!

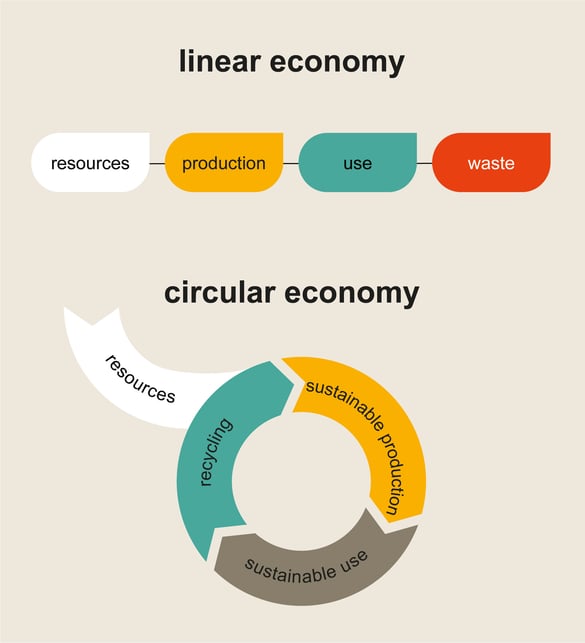

Waste in a linear and a circular economy

A linear economy, as the name suggests, moves along a line. We mine raw materials, process them into a product, which often ends up as waste after use. In a circular economy, we close the loop and raw materials remain in the chain.

Read also

Why recycling is not truly circular

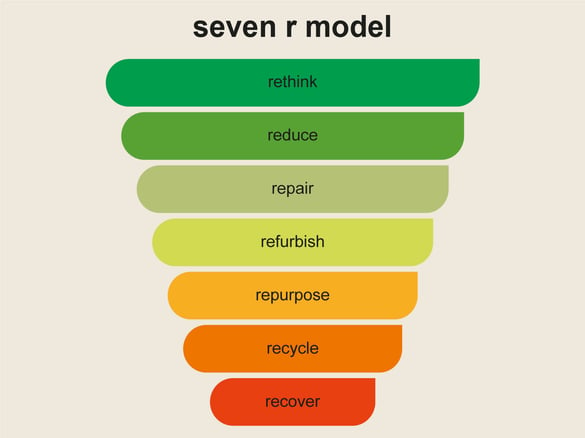

Lansink approach in a new jacket

When we put Lansink's Ladder in a circular jacket, the bottom two steps, being 'dumping' and 'burning', disappear. We can equate the step 'energy', now the lowest step, with the recovery step from the R-model. After all, this step stands for extracting energy from non-recyclable waste. So the least favorable choice. From a circular perspective, however, we want to look beyond 'prevention'. That is why we are expanding the ladder with a number of extra steps. These steps are a good representation of the aim to extend the life of raw materials.

Circular Ladder van Lansink

The steps, viewed from the highest preference to the least desirable method, are: rethink, reduce, repair, refurbish, repurpose, recycle and recover. Rethink, the highest priority, means that through smart design fewer raw materials are needed or raw materials are used sustainably. Reduce, the second step, stimulates a conscious use of raw materials by reducing use and reducing waste. The last step, recover, is the least desirable scenario in this circular model.

Milgro and the Ladder van Lansink

Milgro has nearly three decades of experience in waste management and management. Lansink's Ladder, we know it. And although used for our waste management, Milgro thinks one step further. After all, being circular is not about extending the life of waste. It's about extending the life of raw materials.

Prevention as a starting point

Being circular means first and foremost that you are in control of the waste flows. And then the focus shifted from waste to raw materials. See prevention as a starting point, rather than an end point. It is not without reason that we at Milgro say: “Waste is a raw material that has lost its way.”

Resources as natural capital

In the current linear economy, only 8% of all raw materials used have a return journey. Milgro offers its clients insight into the use and consumption of raw materials, with the aim of extending the lifespan of those raw materials. In a closed chain. After all, in a circular economy, not only the outward journey, but also the return journey is organised.

Where to start?

It starts with insight and direction. By understanding consumption and use, we create a view. And through directing opportunities. Opportunities to use or reuse raw materials for as long as possible. And that pays off; not only ecologically, but also economically. In other words: earth & earn together.

See the opportunities for your organization?

By means of a waste scan we calculate, on location, the opportunities for your organization. After the waste scan, you will receive a clear report from us showing your potential on waste management, both in savings of time and costs as well as ecological efficiency.

Op de hoogte blijven

Op de hoogte blijven van alle nieuwe ontwikkelingen? Volg ons op LinkedIn en Instagram of abonneer u op de nieuwsbrief. Bent u nieuwsgierig naar wat Milgro voor uw bedrijfsvoering en afvalproces kan betekenen? Neem dan contact op.