Waste costs a company money. And a cleanly separated and properly recyclable stream makes money. In practice, separated streams regularly turn out to be too contaminated for recycling. Rejection by the processor and incineration of the waste follow. Bad for business. And harmful to the environment. More attention to the clean separation of residual streams can prevent rejection. It's simple and complicated at the same time. We explain how. And of course we are happy to help.

Contamination of waste streams

Contamination occurs in many different waste streams. One of the most obvious is cardboard. Almost every company has a container for the separate collection of cardboard. But we see in practice that other waste disappears in this container as well. Plastic film, coffee cups, tape, half lunch boxes, you name it.

That's a waste... And for three reasons:

Cost. Specifically, about thirty cents per kg. That is the difference between the revenue from cardboard and the cost of processing residual waste. This may seem little. But per container (which can hold 3,000 kg of cardboard) your organization loses about 900 euros when a separated stream of cardboard is too contaminated so that it cannot be recycled. This includes the extra tax (Wettelijke Afvalkosten Belasting) levied on it. There may be additional handling costs for manual post-separation. A nice clean residual cardboard stream does not cost money, but is traded on the world market and generates revenue. Those revenues vary from month to month.

Second, a disrupted processing process. When the residual stream is too contaminated, it affects the effectiveness of processing. Possibly, processing takes extra time because pieces of cardboard are still manually saved. Also, the contaminated container has to go somewhere else because it does not enter the recycling process, but is incinerated.

And third, most important to us: sustainablilty. A cardboard fiber can be reused at least seven times. The possibilities for recycling end immediately when a residual cardboard stream is too contaminated for reuse. And that's bad for the environment. In fact, recycling prevents the production of new cardboard. The impact of producing one kg of new cardboard is 1.02 kg CO2eq. That's leaving a light bulb on for two days. In addition, contaminated cardboard is often incinerated. Again, the environmental impact of this is substantial, at 1.6 kg CO2eq per kg of paper that is not recycled but burned.

De CO2 impact van reststromen wanneer ze naar het restafval belanden

Cardboard and more

Cardboard is not the only stream in which contamination occurs. We also see this happen with wood. For example, a stream of A wood (untreated and non-impregnated) can degrade to B wood or even C wood (lower quality) because the stream is too polluted. A-wood can be recycled, B-wood is often processed into particleboard and C-wood becomes biofuel. We also see foil, a widely used packaging material, often ending up as residual waste. All these streams can be processed in a better and more sustainable way. And that is simple and complicated at the same time.

Milgro's approach

Milgro supports companies to bring residual streams pure and clean towards processing and recycling. Thus we help companies to take steps towards a circular economy. We do this with a number of effective interventions that prevent rejection.

We check whether the rejection is justified

When a processor indicates that a shipment has been partially or fully rejected, we ask the service provider to provide photos in this regard. Based on the photos, we check whether the rejection and the percentage indicated are justified. It regularly happens that a separated waste stream is rejected incorrectly.

We give direct feedback on the shop floor

On the shop floor, we see best how waste is handled. With our knowledge and insights, we can give direct feedback to the supervisor on the shop floor. When waste streams become contaminated on a regular basis, we get to work to find the cause. Based on the photos and an additional site visit, the cause of the contamination is often found.

Mystery behind the wall

It was a mystery at the company. Out of 15 containers of cardboard, as many as five were rejected. Each time there was too much residual waste with the cardboard. And there were clear signs on the wall behind which the containers were placed. The mystery was unraveled quite simply. It turned out that the containers were regularly changed when they were repositioned. Behind the wall with the indication for residual waste was the cardboard container. And vice versa.

We create awareness with training and education

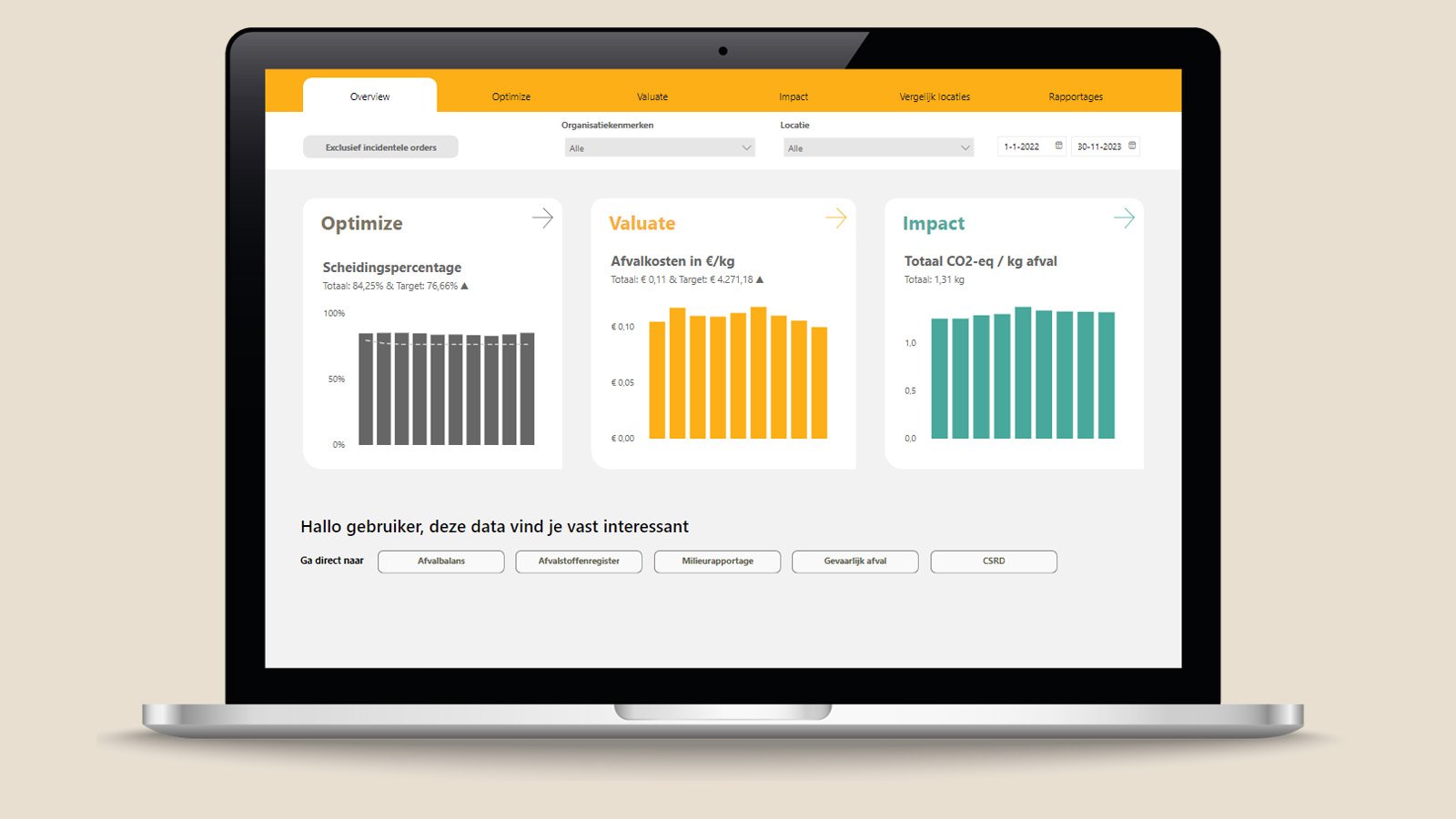

Nothing is as difficult as influencing behavior. Throwing a coffee cup* among the cardboard is often done without anyone thinking about it. Through training courses and information we try to increase the awareness of employees about separating waste. Because we notice in practice that there is sometimes quite a bit of skepticism about the usefulness of separating waste. We support this education with data from our online dashboards. These data show that cleaner flows are better for the company and for the environment.

Coffee cups, a hot issue

Coffee cups are a major cause of rejection of clean streams anyway. After the coffee is finished, the cup is often filled with a napkin or the core of an apple. Stirrers or empty cups of milk are also often left in empty coffee cups. The new rules on disposable plastic will hopefully reduce this. But proper separation also helps.

We put the right container in the right place

Sometimes you can accomplish a lot with simple interventions. It often happens that the container for cardboard is in an inconvenient place, so it is not used optimally. The trick is to place the right collection device in the place where recyclable streams originate. A box for label rolls at the place where products get a sticker, for example. Or a mesh container for cardboard at the spot where boxes are unwrapped.

We provide additional tips for taking the next step

Want to take the next step? Using the right signage is effective. It should be clear at a glance which type of flow is for which container. Instructions visualize what is and is not allowed in them, understandable for all languages spoken on the shop floor. Consistent use of color also helps. Being creative can also be effective: the environmental gain per properly separated container in euros or CO2 gain, for example.

Want to know more?

Do you want to know more about how to prevent rejection of residual streams? Milgro calculates for you the ecological and economic business case of preventing rejection of residual streams. And we are happy to tell you everything about all the above possibilities, from dashboard to training and from signing to information. Please contact our business development manager.

Stay informed

Stay up to date on all new developments? Follow us on LinkedIn or Instagram. Or subscribe to the newsletter. Are you curious about what Milgro can do for your operations and waste process? Contact us